- 925 North Todd Avenue, Azusa, CA 91702

- info@facs.llc

- Contact Us

- 626-633-0294

PowerSleeve® Information

PowerSleeve® Information

PowerSleeve®, our engineered composite kit, consists of a fabric that is a hybrid alloy, non-crimped system, employing a high grade E-glass and Kevlar® yarns, or C-2 carbon fabric arranged in a multi-axis layout that maximizes the ultimate composite strengths. This fabric is factory pre-treated using a state-of-the-art process which assures that all the micro-fibers in the wall will be matrix-wetted. Tests of these pre-treatments show a finished PowerSleeve® installation is much stronger than an untreated lay-up. Powersleeve is available in various carbon and glass fabric to fit numerous applications.

PowerSleeve kits are configured with the fabric and resin that works for you. The PowerMatrix™ grade is selected for your application type. We used custom formulations that give our product exceptional properties of flexibility, adhesion, toughness, chemical resistance, thermal resistance, vibration, etc. Special grades are available to handle special situations.

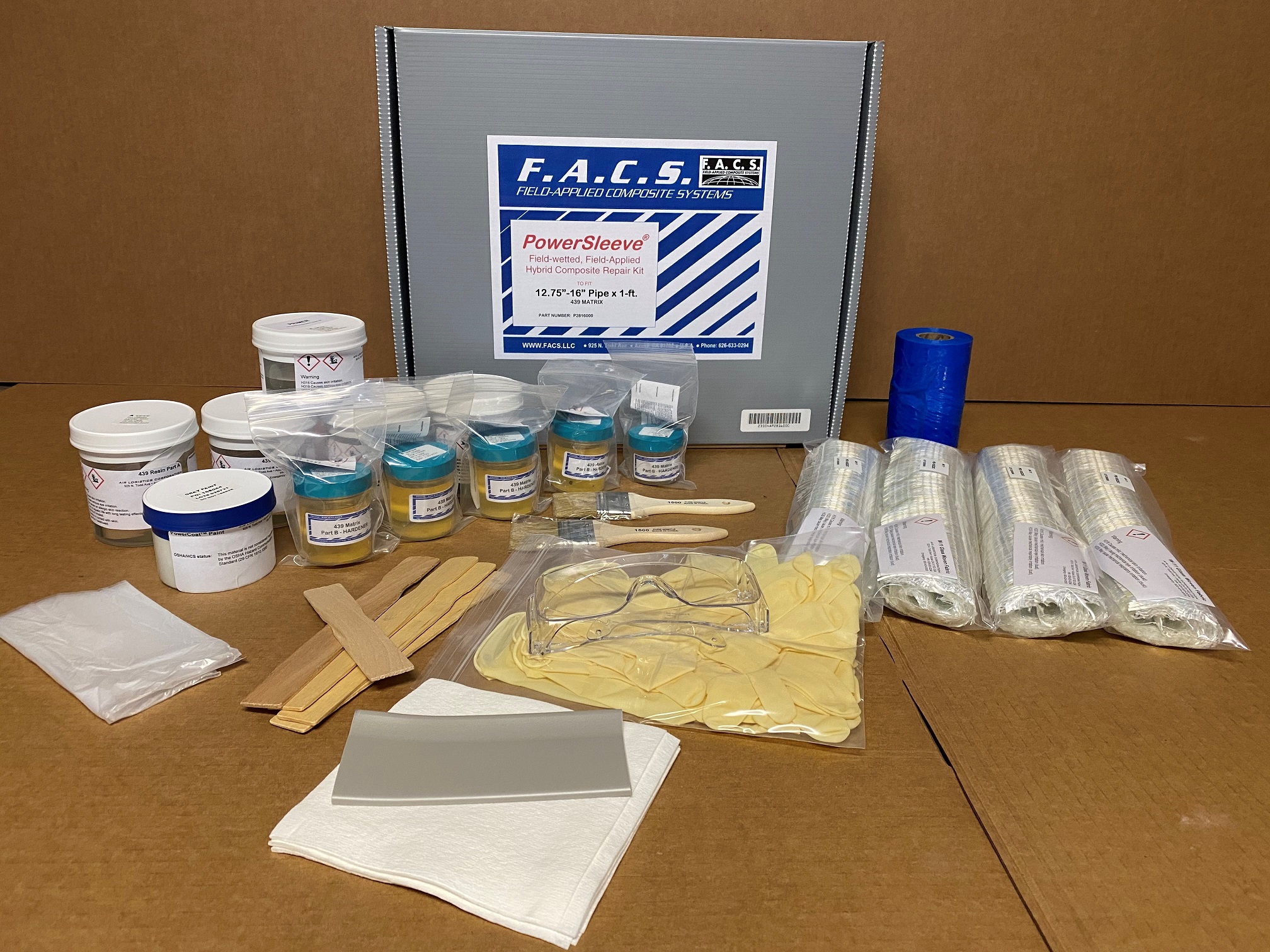

PowerSleeve® Kits ship to the field with all components pre-measured and factory sealed. Everything is included: PowerSleeve® Fabric, PowerMatrix™, primer, stirring sticks, Stricture Banding™, paint, safety glasses, wipes, etc. The technician simply lays out a pre-measured fiber reinforcement segment, mixes the pre-measured resin components (with the furnished mixing stick) and applies the resin to the reinforcement. No measuring is required in the field, and performance tolerances are tightened with controlled fabric/matrix ratios.

General Characteristics - Standard Matrix System

- Tg. 185° F

- Working Time 30 minutes nominal @ 77° F

- Cure Time 8 hours nominal @ 77°F to full cure

- Chemical Resistance Resistant to acetone, mek, toluene, gasoline, ethyl alcohol and many others

- Tensile Strength 75,400 psi for the Standard PowerSleeve® Fabric

- Tensile Modulus 3.9 (e-6 psi)

- Compressive Strength 29,400 psi for the Standard PowerSleeve® Fabric

- Interlaminar Shear 4,580 psi for the Standard PowerSleeve® Fabric

Features

- Complete Installation Kits

- High Strength

- Very Versatile

- Many Different Widths and Lengths

- Excellent Toughness - Resists Cracking

- Alternate Systems for High-Temperature Applications

- Maximum Temperature Range of 450° F

- Factory Pre-Measured and Sealed Components

- No VOC's

- Manufactured in Azusa, CA USA

Sizes

Kit sizes are available for any diameter pipe. Standard PowerSleeve® Kits come with 12" wide fabric that will cover 1-linear foot of pipeline. Custom widths are available upon request. Special fabric weaves are available for use on difficult configurations.

Matrix Systems

Standard Matrix

A two-component, ambient temperature matrix used in our PowerSleeve® composite reinforcement products. This ambient temperature cure matrix wets out easily and can be applied to our PowerSleeve® W-11 and G-03 Fabrics. It is relatively fast setting, approximately 30 minutes @77° F and is used where a maximum service temperature of 180° F is desired. No VOC’s, 100% solids. This product ships DOT non-hazardous.

439 Matrix

A two-component, medium temperature matrix used in our PowerSleeve® composite reinforcement products. This ambient temperature cure matrix wets out easily and can be applied to our PowerSleeve® W-11 and G-03 Fabrics. It is relatively fast setting, approximately 60 minutes @77° F and is used where a maximum service temperature of 300° F is desired. Intermittent excursions to 325° F can also be tolerated. The color will change from a mild yellow to dark amber when temperatures rise above 140° F. This product ships DOT hazardous (corrosive).

X-TEMP-2

A two-component, heat and chemical resistant matrix used in our PowerSleeve® composite reinforcement products. This elevated temperature cure matrix wets out easily and can be applied to our PowerSleeve® W-11, G- 03, C-2 carbon and our highly conformable BearTM Fabrics. To achieve its ultimate chemical resistance properties requires post cure per the instruction sheet. It is relatively fast setting, approximately 80 minutes at the minimum application temperature of 150° F. Designed for use where a maximum service temperature of 450° F is desired. This product must be post-cured in order to achieve the best chemical resistance properties. The color will be dark amber when temperatures rise above 200° F. This product ships DOT hazardous (corrosive). Technical Data Sheet.